Tubesheet Cladding

Discussion

Tubesheet corrosion is generally caused by dissimilarities between higher alloy, more noble tube material, and the tubesheet metal. This situation is becoming more and more prevalent as high-stainless steel and titanium tubes are being retrofitted into older condensers and heat exchangers. Loss of tubesheet metal due to corrosion will, in time, lead to the compromise of tube-to-tubesheet joint integrity.

Generally the alternatives for tubesheet protection are cathodic protection (CP) or protective coatings.

Cathodic protection of complex surface areas such as tubesheets with thousands of tube openings is difficult to achieve. Also, a CP system may embrittle titanium and ferritic stainless steel tube-ends if it exceeds – 750 mV. Additionally, CP systems may receive little attention from operation and maintenance personnel and may cease to function effectively over time. During outages with the waterboxes drained, galvanic corrosion can continue without the benefit of CP protection.

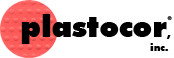

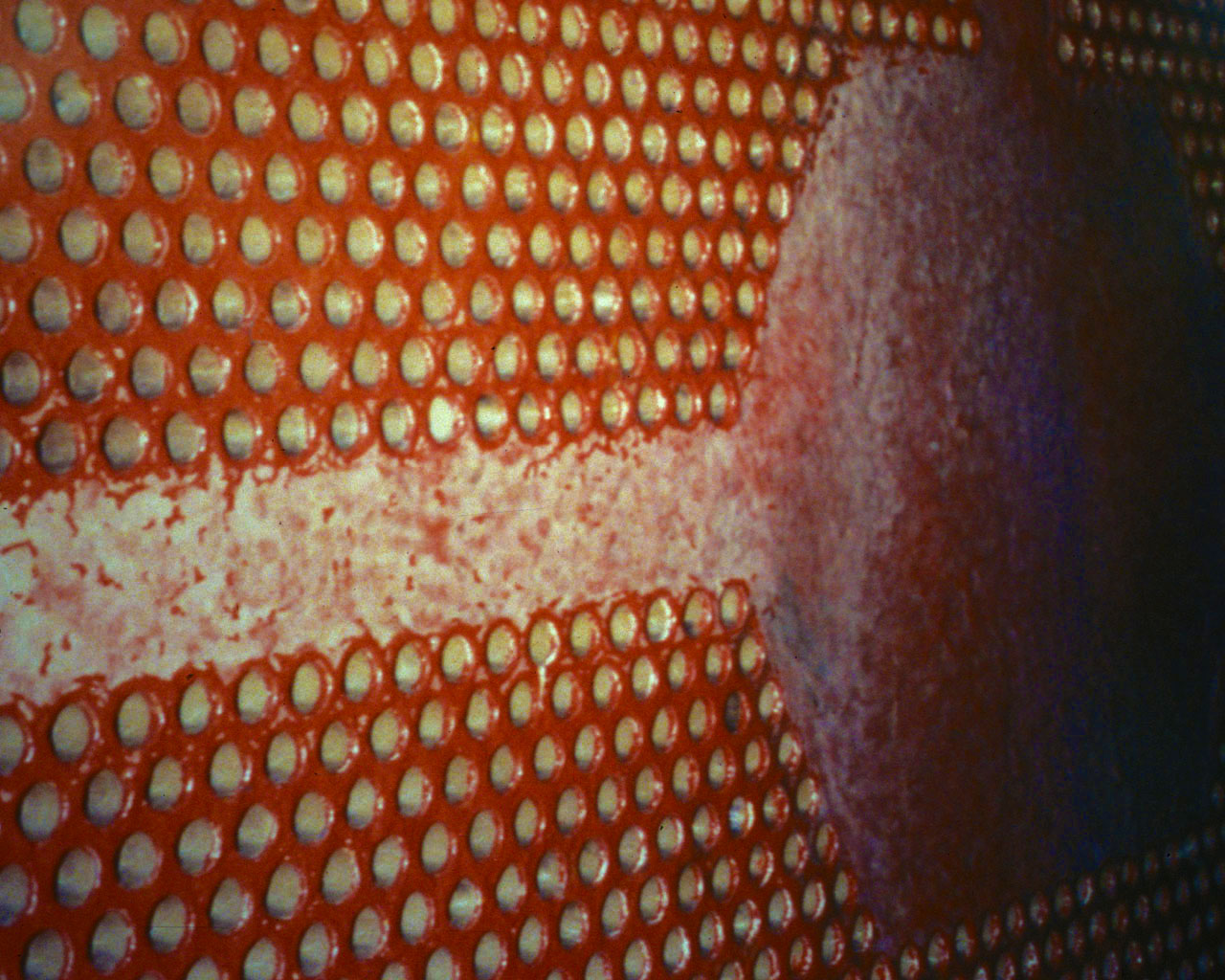

While the passive protection of a coating system solves these problems, thin film coatings of 25 to 80 mils have failed due to improper application, and because a thin film thickness is insufficient to withstand the long-term abuse of cooling water systems such as impact during cleaning and inspection. Counter productively, a partially failed coating may actually accelerate galvanic attack. (see photo below)

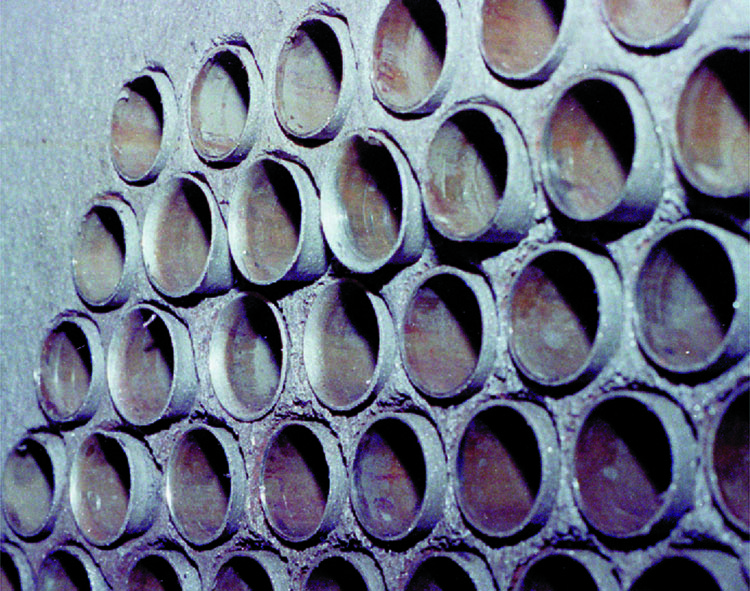

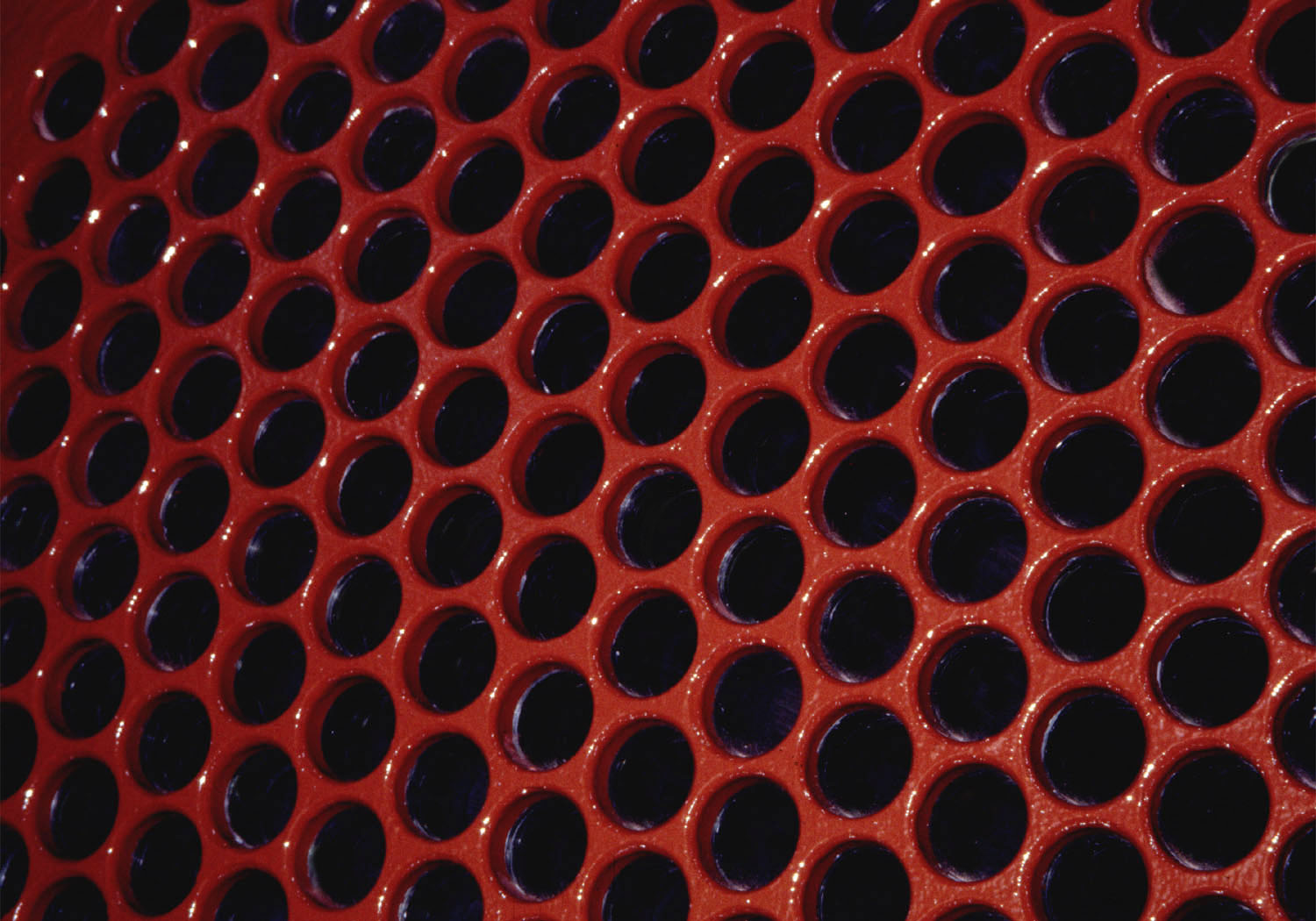

The Plastocor® Process entails the precise molded application of an ultra durable protective Cladding. The tubesheet and tubes are completely encapsulated and locked in by a thick, 100% solids epoxy shield of 180 +/- 40 mils. This polymeric shield is in addition to the thickness of material required to rebuild lost tubesheet metal.

The Process fashions a radially flared, high gloss, inlet and outlet tube opening, serving to dramatically reduce flow resistance and fouling. For on-line tube cleaning systems, sponge ball wear is reduced.

The substantial nature of the System adds strength and integrity to the tube-to-tubesheet joint. Tube push-out strength enhancement of 2000 lbs is routinely achieved.

Typically, the tube-to-tubesheet joint is a press-fit whereby the tube is expanded (by rollers) into the tubesheet. Over time it is possible for this press-fit to be compromised. Black-trips, water hammer, or partial blockage of a tubesheet are the most common sources of stress to the tube-to-tubesheet joint. These stresses can cause the joint to “break” which allows the tube to slip in the tubesheet. Small “joint leaks” usually result. These leaks can be very difficult to locate as they often vary in intensity as condenser is subjected to transient forces during startup and other situations. By epoxy cladding the tubesheets, all of the tube joints are permanently sealed and 2000 pounds of joint strength is added.

The Plastocor® Cladding withstands physical abuse, impact, and other stresses associated with the operation of a cooling water system. The System is designed to endure over the very long-term. Case histories date flawless performance back to 1963.

The Plastocor® System is engineered as an extremely long-term solution to tubesheet corrosion problems.

Examples of Deteriorated Tubesheets which have been restored with the Plastocor Cladding

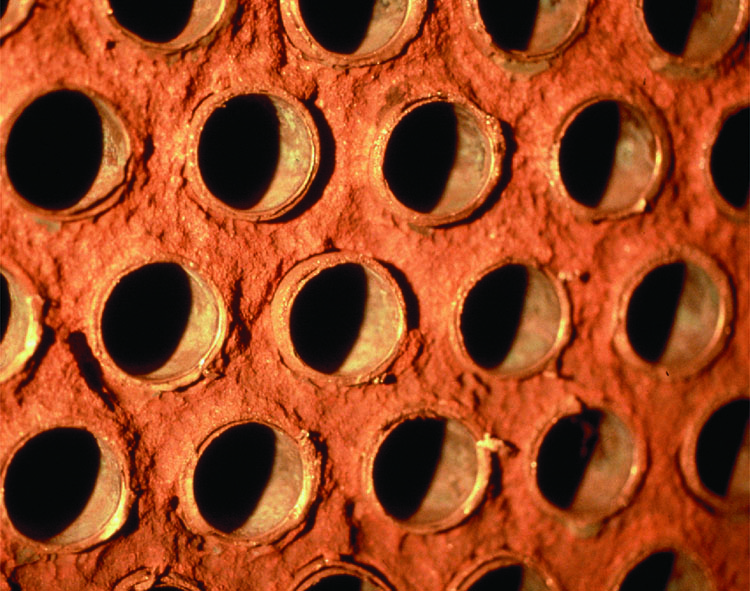

A carbon steel condenser tubesheet with 304 stainless tubes using fresh water, with cooling towers. Over ten years, acidic runoff from the adjacent coal mine caused nearly 3/4″ of tubesheet material to be lost due to galvanic attack. The original tubesheet material thickness was 1″. All the tubesheets, waterboxes, and cross-over tunnels for these two (2) 850 Mw units were Plastocor Clad in 1984 and 1985. The coating remains intact.

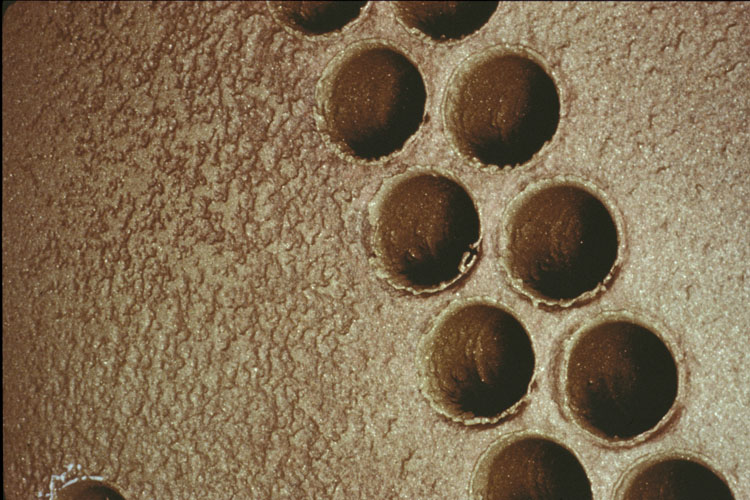

This aluminum bronze condenser tubesheet was originally coated with a thin 60 mil system epoxy which experienced spot failures. Deep cavities of lost metal occurred at these failure points due to the selective and concentrated galvanic interaction with the titanium tubes in seawater. The existing coating was stripped off and the Plastocor Cladding was installed (180 mils) in 1993.

No this is not a piece of volcanic rock… it is a severely deteriorated carbon steel tubesheet after the tubes had been removed. After the re-tube, the tubesheets were Plastocor clad which replaced the lost metal with epoxy and established an additional protective overlay of 180 mils, thus avoiding the cost and delay of new tubesheets.

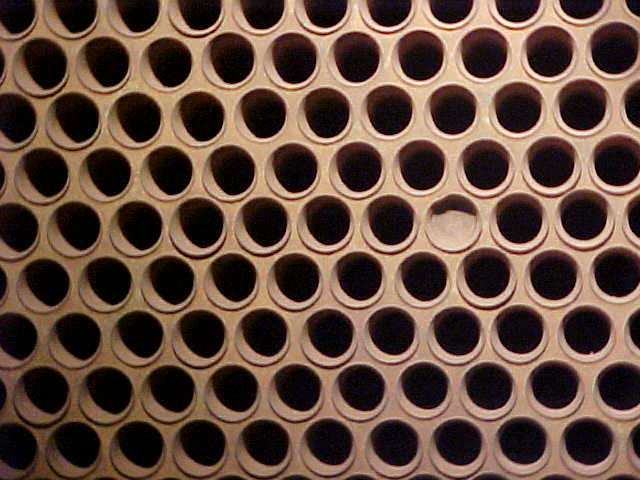

Here, several tube-ends were deformed by the improper use of high-pressure water blasting which was used to clean the tubesheet. As a result, severe joint leaks were created. Plastocor reworked the tube-ends and installed the Cladding which restored the integrity of the condenser. Contact us for guidance on the proper use of this cleaning method.

Entrained solids in the cooling water caused this impingement damage on the tubesheet and tube-ends.

While this tubesheet appears to be in good condition, operational stresses caused tube-to-tubesheet joint leakage. This was most apparent when the unit started up. The Plastocor Cladding was installed and the joint leaks were sealed. Examples of operational stressed are: black trips, water hammers, or partial blockage of the tubesheet.

Examples of Deteriorated Tubesheets which have been restored with the Plastocor Cladding

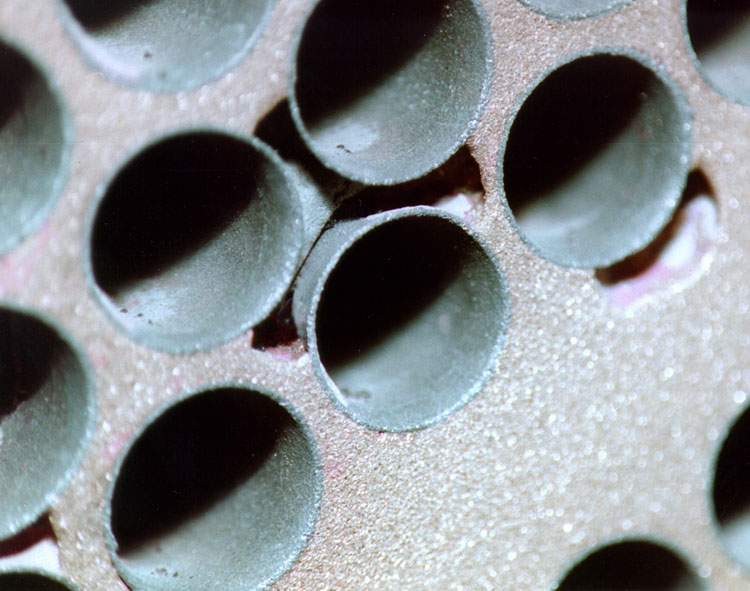

No matter what the condition of the tubesheet, this is an example of what it looks like after installation of the Plastocor Epoxy Cladding. All lost metal has been replaced with epoxy and an overlay of 180 mils has been applied. Tube joint strength has been restored and fortified against further damage. The cladding is expected to last the life of the tubes which can be decades long.

This photo was taken after 10 years in service and shows the Cladding to be intact – with just a bit of surface fouling.

Examples of

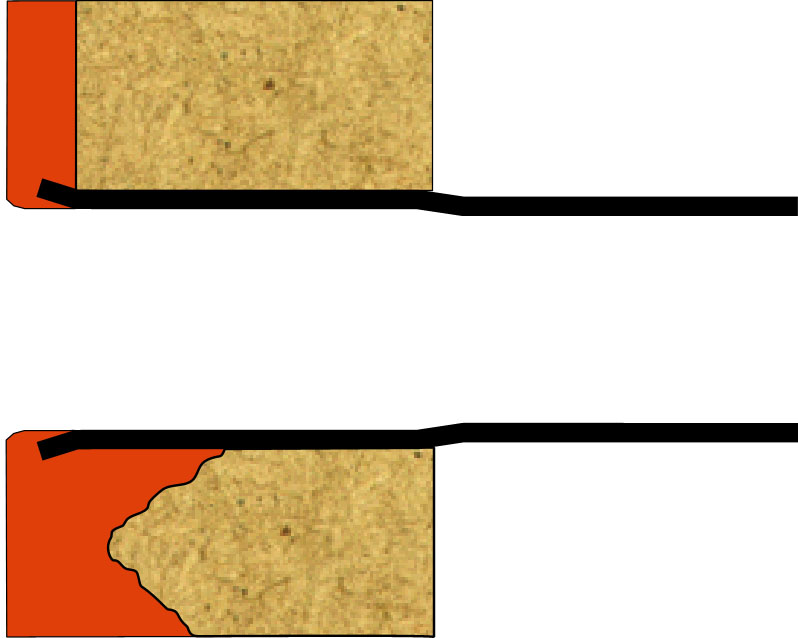

Tube-to-Tubesheet Configurations

The Plastocor® Process can be applied to any tube-to-tubesheet configuration experiencing any level of deterioration providing structural integrity is not threatened. The diagrams at the right (and below) show the cross-section of three examples. Each configuration is shown as it would appear with a new or slightly corroded tubesheet (upper half) as well as with a more severely corroded tubesheet (lower half). Tube-trimming and flaring may be required for an optimal installation. Plastocor©, Inc. can perform all of these tasks.