Pressure Testing of Condenser and Heat Exchanger Tubes

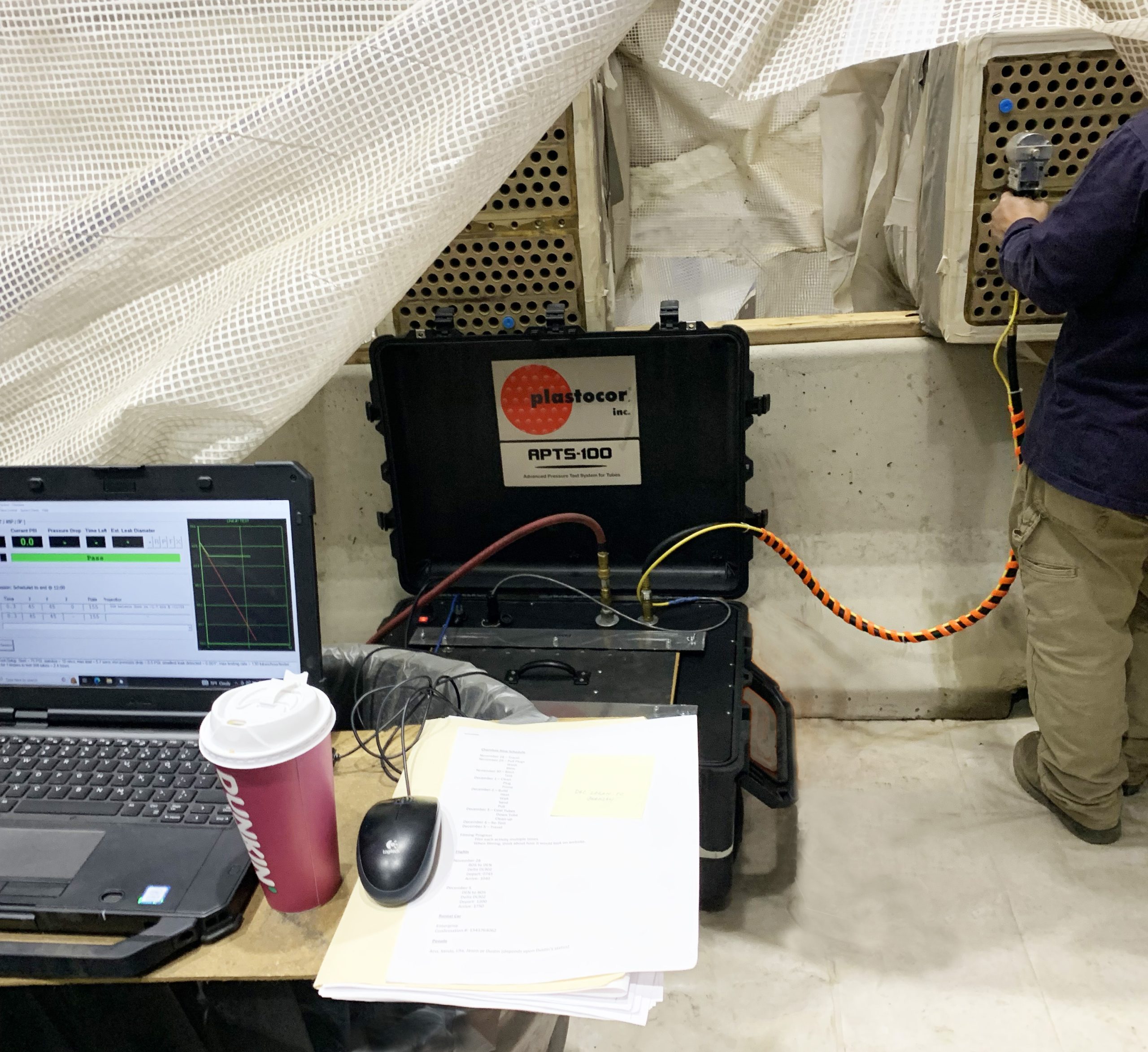

Plastocor, Inc. has the ability to seal leaks in condenser and heat exchanger tubes. As a necessary compliment to this capability we have developed a method and apparatus for pressure testing individual tubes. This Advanced Pressure Testing System (APTS) is defined by the following features:

– Programable to find a leak of specified size in a tube of specified length and diameter

– Computer controlled to conduct the test uniformly without operator judgement, or error

– Semi-Automatic with recorded results

– Ruggedized for field operation

– Optimized for accuracy and productivity

– Fully compliant with ASTM A1047/A1047M-08(2019)

Discussion

Flow of Air Through an Orifice

The rate at which air flows through an orifice (leak) is determined by four factors: the size (area) of the orifice, the pressure differential across it, the temperature of the air, and the coefficient of flow (a proxy for the resistance to air flow caused by the shape and edge conditions of the orifice).

Flow of Air versus Pressure Drop

For practical reasons, leak testing devices do not measure air flow; instead, the most common measure the pressure drop caused by the air flow. The rate at which pressure drops is determined by the flow rate and the mass of air in the tube, which is a function in turn of internal volume, absolute pressure, and temperature.

Pressure Drop and Dwell Time

Finding small leaks in large tubes can take a surprisingly long time, especially when using low pressure and/or low precision analog gauges of the type found on standard equipment. Even if digital gauges are used, the process is tedious.

How long? A pinhole leak 0.004” in diameter in a 1” BWG 22 tube 50 feet long pressurized to 50 PSI wouldn’t result in a 2 PSI pressure drop until 60 seconds had elapsed, while a 5 PSI drop wouldn’t occur for over 2 minutes. At 75 PSI, the times would drop to 30 and 60 seconds, respectively, but if the leak diameter was 0.002” instead, the time would rise to 2 minutes for 2 PSI, and over 4 minutes for 5 PSI.

Additionally, note that in each test, the pressure drop countdown cannot start until initial pressure stabilizes, which adds from 10 to 30 seconds of dwell time per tube. It is not surprising that current practice results in many false negatives.

Pressure Testing by Plastocor: Precision and Productivity

The Advanced Pressure Test System (APTS), in use in the field since 2015, has proved to be a faster, more accurate, and less fatiguing method of pressure testing heat exchanger and condenser tubes.

Better Performance in All Stages

Pressurization — PSI target hit precisely on every test, in ½ the time

Stabilization — Wait for stability exactly as specified on every test

Observation & Detection — Detect leaks of given size in less time

Detect smaller leaks in given time — Configure test protocol to customer priorities

Cycle Time — Exhaust tube and move to next one in ½ the time

Quiet Operation — Air exhaust happens outside waterbox, facilitates communication

Demonstration Videos

Below are demonstrations of the APTS equipment in action.

The Advanced Pressure Test System (APTS) being used on a heat exchanger tube bundle.

The APTS computer interface during test,